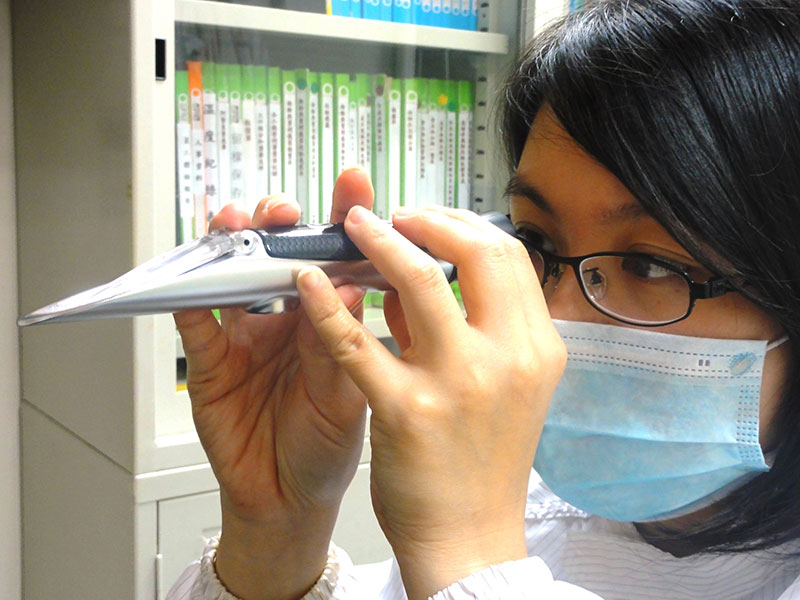

The factory was established in 1995. Since its establishment, it has always adhered to the principle of good faith, focusing on quality and service efficiency, and actively serving customers. It has obtained ISO 22000 food certification and HACCP certification from the SGS organization. It is the best health food production factory worthy of your trust.

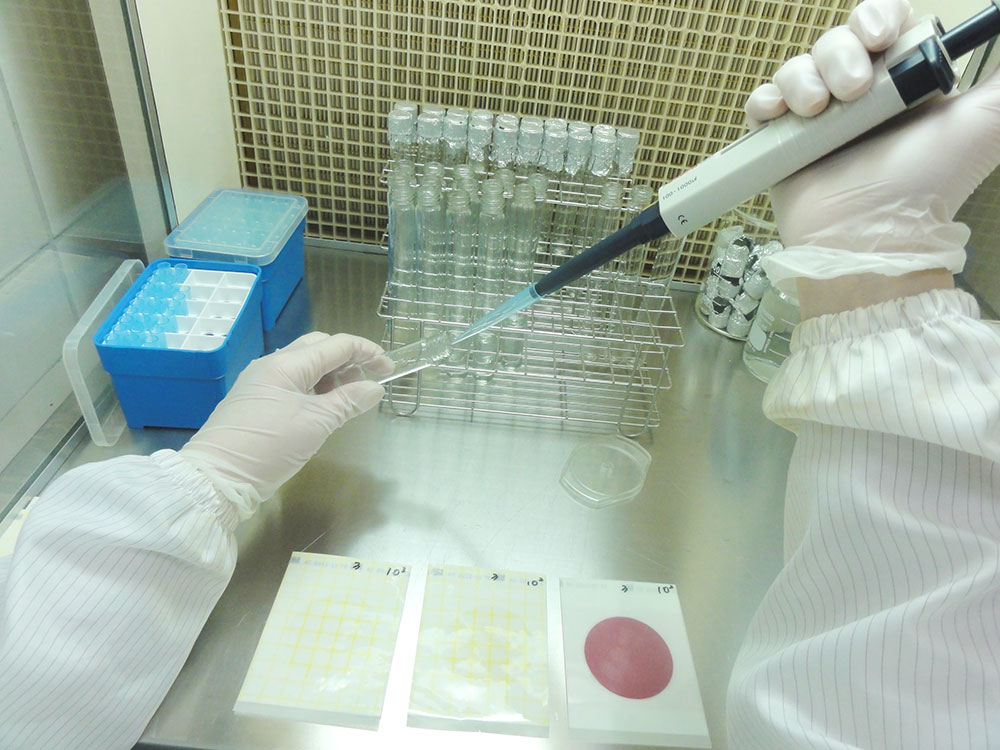

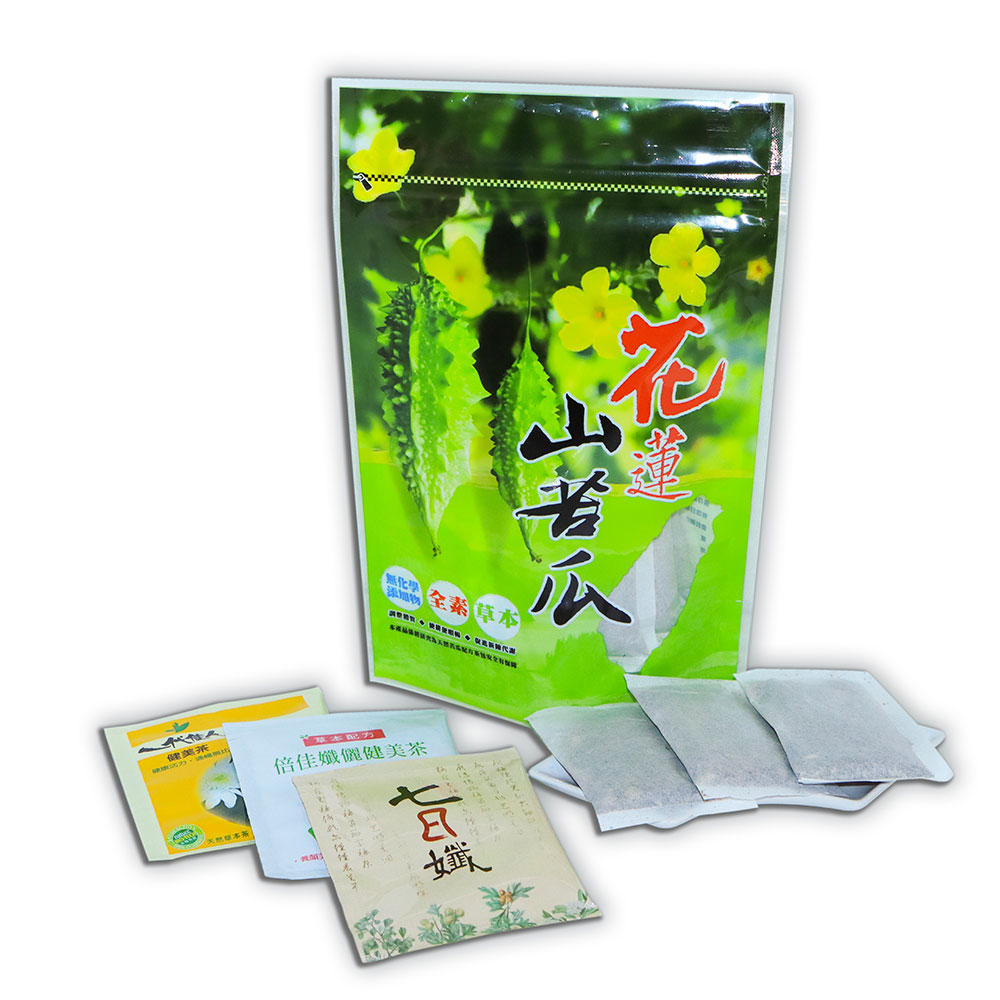

The factory is committed to improving the production technology of all kinds of capsules, tablets, tea bags, liquid beverages... and other products, and develops automated manufacturing processes and strict on-site environmental sanitation management processes to provide customers with the best production quality.

+886-2-2226-5656